ABOUT US

Welcome to Dev Components

Dev Components, a Private Limited Company was incorporated in the year 1991 by Mr. Dhananjaya A, a B.E (Mech) graduate from R.V College of Engineering, Bangalore to manufacture Electrical Stampings, Laminations, and other allied activities, catering quality products to various industries including large OEMs across the World.

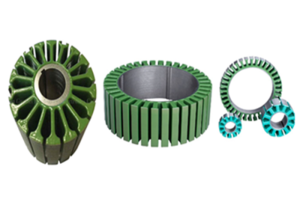

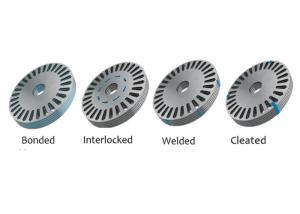

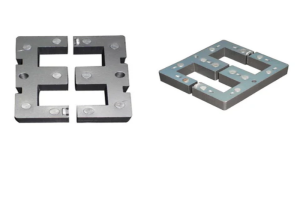

Dev Components is highly experienced in manufacturing precision Electrical Stamping and

Lamination for a wide range of applications such as fans, motors, submersible, pumps, transformers, chokes, ballasts, tacho generators, alternators, electric motors for automobile industry and serves a wide range of industries including auto- motive, consumer products, appliances, heavy industrial electric capital equipment among others.

Dev Components has built wide and huge client base over since the inception in the year 1991 by supplying quality products that are used in a large majority of manufacturing industries. To put it in a simple way where ever there is a conversion of electricity our products are needed. Our products form the core for all electrical appliances like Motors, Fans, Mixer Grinders, Household Appliances, Electric Vehicle Motors and other motors for automotive, industrial capital equipment motors, etc, thus enabled Dev Components to evolve as one among the best stamping laminations punching set up in whole of India and also extended supplies to various customers across globe.

Quality Objectives

Mission

Aim to Research & Develop High Quality Stamping Tools & Cater Competitively Priced A to Z High Quality Electrical Stampings & Laminations Across the Globe

Vision

Contribute to Conserve Energy & Preserve Future

Our Values

Setting high standards of business and transaction, practice highest principles of work ethics, maintain transparency and persistently strive for excellence.

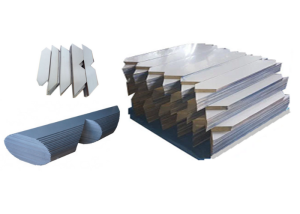

Customized Products & Specialization

Linear Motor Stampings

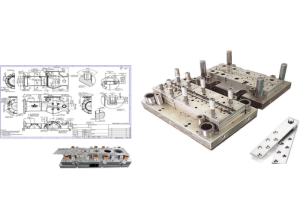

Progressive Tool Die Designing & Making

A to Z Motor Stampings “ You Name It, We Make It ”

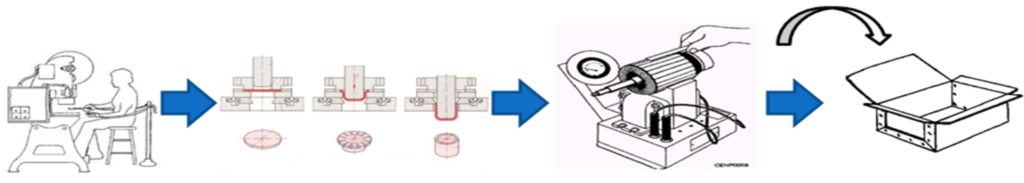

Devs Production Capabilities & Process

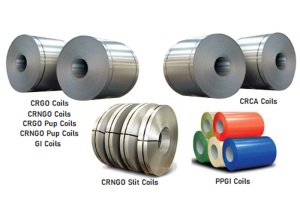

Coil Slit & Batch Tracking

Task Card Allotted to Track Performance

Pre-Job QC for Damages, & Burrs

Punching Using Presses

Component Stacking, If Mandated

On Spot QC & Inspection Certification

Task Card Closure & Packing for Sale

400+ Ton Production Per Month Capacity, With Special Capabilities to Gear Up Big Bulk Orders With a Short Notice