Operation

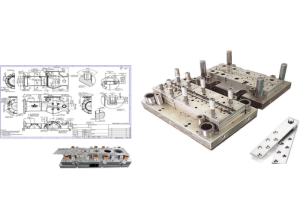

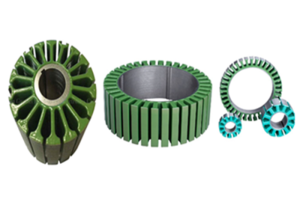

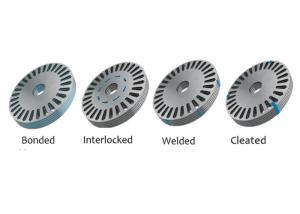

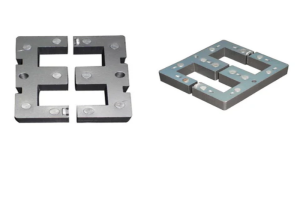

Manufacturers of EI & Strip Laminations | Cut Core | Stators & Rotors | Mitre Cut | Slit Coils | Stamping Tools Dies & Design, Making & Testing Services

Our Pledge

Preference and Consistency

Gurantee prefernce and consistency by adhering to meet or exceed stakeholders exeception

Gurantee product safety and full compliance by adhering to right working Principles, with Full Transparency

Pledge

Quality Policy

PRODUCT

Reduction in defect rates, PPM, on-time Delivery.

PROCESS

Improving Productivity, Reduction of waste, setup time or rework, improved cycle times

CUSTOMER

Product Returns, reduction in complaints improved on-times delivery,

SUPPLIERS

Reduction on complaints or defects improved on time delivery

RESOURCES

Availability, Capability, Personnel, Competency, Efficiency absenteeism

Manufacturers of EI & Strip Laminations | Cut Core | Stators & Rotors | Mitre Cut | Slit Coils | Stamping Tools Dies & Design, Making & Testing Services

Product Flow

01. Coil Slit Planning

08. Periodic Grinding of Tools & Maintenance

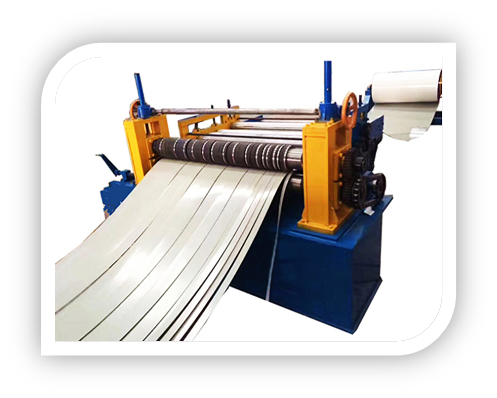

02. Coils are Slit

07. Water Resistant Packs of Stocks Ready for Dispatch

03. Batchwise Slit Coils Ready for Stamping and Laminations

06. Manufactured Stocks & On Spot Quality Check & Control

04. Tool Setting into Machine & Sampling & On Spot Sampling Starts

05. Stamping & Lamination Products Manufacturing Done Basing Product Type in Different Machines

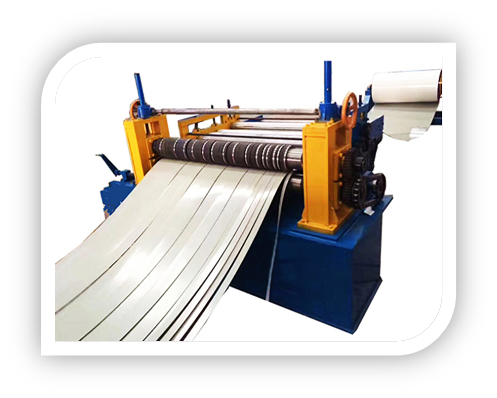

01. Coil Slit Planning

02. Coils are Slit

03. Batchwise Slit Coils Ready for Stamping and Laminations

04. Tool Setting into Machine & Sampling & On Spot Sampling Starts

05. Stamping & Lamination Products Manufacturing Done Basing Product Type in Different Machines

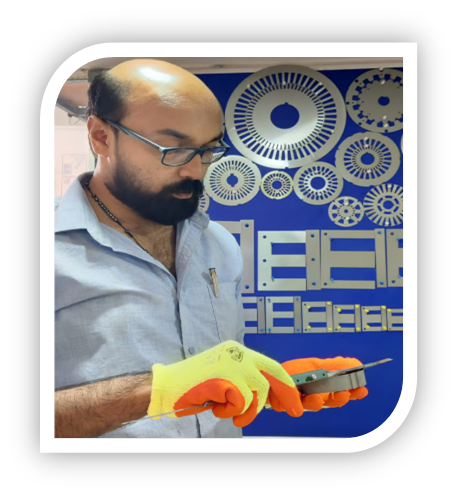

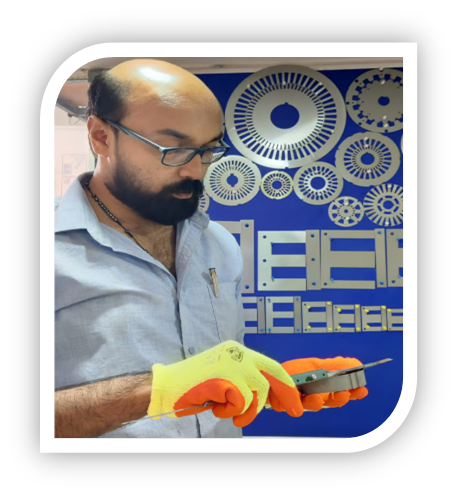

06. Manufactured Stocks & On Spot Quality Check & Control

07. Water Resistant Packs of Stocks Ready for Dispatch

08. Periodic Grinding of Tools & Maintenance

Quality Check Policy

Manufacturers of EI & Strip Laminations | Cut Core | Stators & Rotors | Mitre Cut | Slit Coils | Stamping Tools Dies & Design, Making & Testing Services

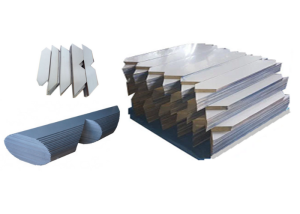

Major Products

Manufacturing

- Stampings Dia from 30mm to 400mm, EI Laminations from Types EI19 to EI 350, in CRNGO All Grades.

- Cut to Length Strip Laminations with Holing in CRGO & CRNGO, products Range Strip Laminations, Mitre Cut Laminations.

- Specialized & Customized Designs as per Customer Requirement of Stamping and Lamination in CRNGO All Grades.

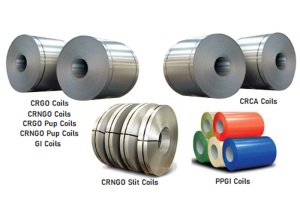

Distribution & Trading

- Prime CRNGO Coils of 0.20 mm to 0.50 mm Thickness, Width Ranging Up to 1000mm in all Grades.

- Customized Cut To Length, Slit Coils in All Grades

Customized Products & Specialization

Linear Motor Stampings