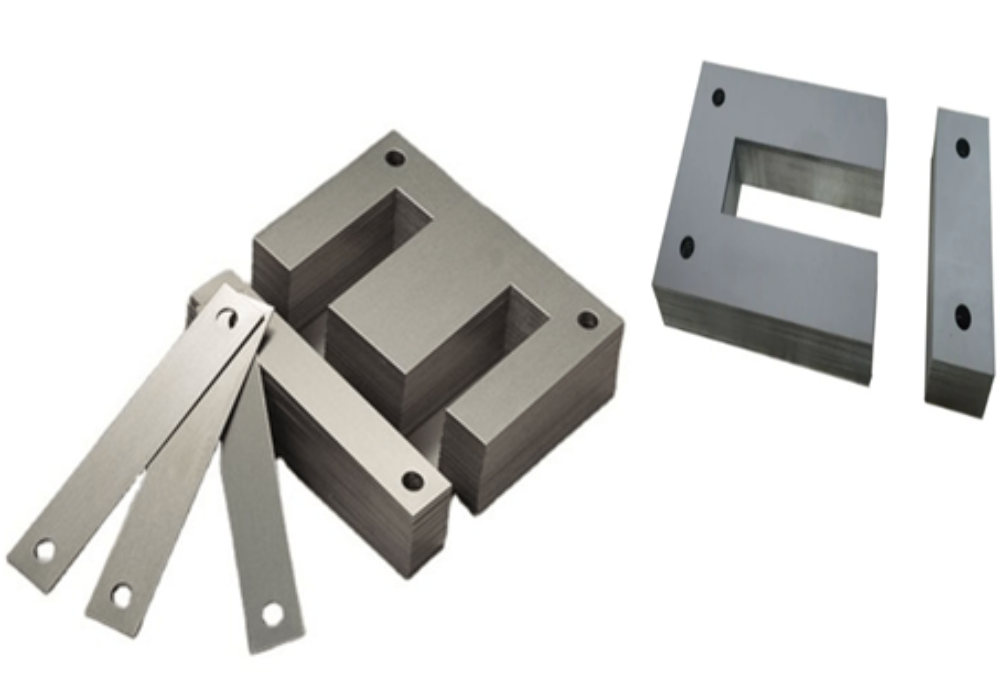

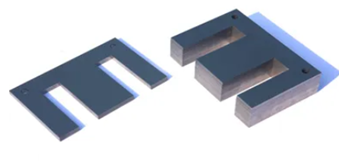

Electrical Laminations

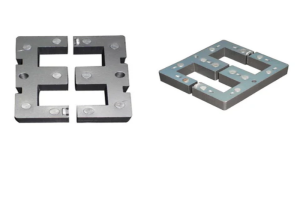

E&I Laminations are used in Transformers which are devices that step up or stepdown the voltage and these transformer core is the E&I Lamination which comes in different sizes.

E&I Laminations types Ranging From EI 29 to EI 350 EI Transformer Laminations and range varieties in UI Laminations, InverterLaminations , Medical Grade Isolation Transformer Laminations, Stabilizer Laminations / 3 Phase Lamination Cores.

E&I typically look like “E” and “I” in English Alphabets, hence the name. The core is punched from high grade, non-aging Cold Rolled Non Grain Oriented (CRNGO) silicon steel laminations conforming to HIB grade of BIS certified with lamination thickness of 0.25mm to 0.5mm. The core will have the Watt loss between 2.5 W – 6W per kg @ 1.5 Tesla at 50 Hz The output parameter requirement will decide the type of lamination to be used and these types range from Type 28 to Type 350.

EI Transformer Laminations

Industrial Application

Used in transformers, voltage stabilizers, UPS, inverters, converters, lighting ballasts, rectifiers & many more.

Technical Specification

EI laminations are manufactured using various grades & thickness in electrical steel to maintain low watt loss and low off load current. EI Laminations range from Type 38 to Type 350 and the output parameter requirement will decide the EI Lamination Type.

UI Laminations

Industrial Application

Used in slim type single phase transformer cores and UI’s Laminations are alternate to EI lamination cores.

Technical Specification

UI laminations are manufactured using various grades & thickness in electrical steel to maintain low watt loss and low off load current. UI Laminations are made to application specific design for usage in slim type single phase transformers in specific.

Inverter Laminations

Industrial Application

Used in inverters that convert the DC electricity from various sources like batteries, fuel cells to AC electricity.

Technical Specification

Inverter laminations are manufactured using various grades & thickness in electrical steel, these lamination cores are with highest saturation magnetic induction intensity value of 20000Gs; because of their good magneto-electric properties.

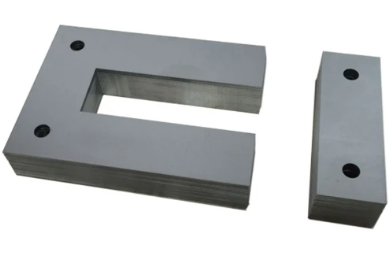

Medical Grade Isolation Transformer Laminations

Industrial Application

Used exclusively in isolation transformers guiding very low leakage of current, thus ensure higher safety.

Technical Specification

Medical grade laminations are manufactured using higher grade electrical steel and are compact in size, weigh low adhering to international safety standards and are made to application specific design for usage in isolation transformers.

Stabilizer Laminations

Industrial Application

Used in Stabilizer transformers to guide the voltage kept fixed at pre-set value basing ferromagnetic resonance Principle.

Technical Specification

Stabilizer Laminations are manufactured using higher grade electrical steel and these cores are customized to application specific usage. Stabilizer grade laminations process magnetic properties with low core loss, high permeability and excellent application performance.

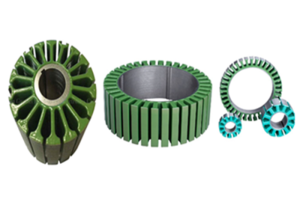

3 Phase Laminations Cores

Industrial Application

Used in 3 phase transformers meant for supplying large loads of power in industrial sectors, power generation sectors.

Technical Specification

3 phase lamination cores are manufactured using higher grade electrical steel and these cores are customized to application specific designs in 3 phase transformers meant for supplying large loads and large power distribution in various or all fields of electrical power systems.

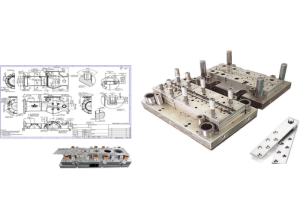

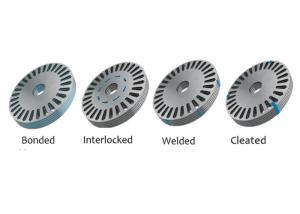

Customized Products & Specialization

Linear Motor Stampings