Bonded & Special Purpose Cores

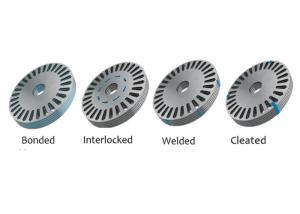

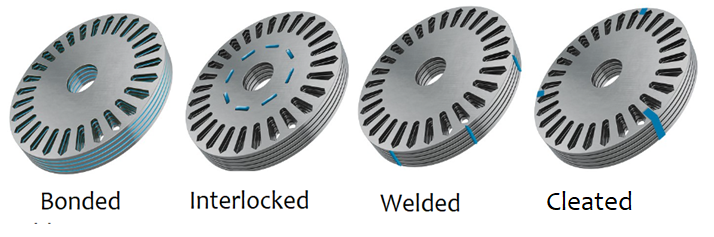

Stator Bonding is also called bonded Stator Lamination Technology. Stator Bonding use high temperature glue or epoxy to realize the lamination process and ensure the stators do not need any interlock or welding to reach lowest iron loss and get highest motor efficiency. Hence, Stator Bonding is normally used for high-end and high efficiency motors.

Bonding with bonding varnish doesn’t allow magnetic flux to be disturbed, it applies no stress and does not deform the material, ensuring that the magnetic properties remain entirely intact. Bonding varnish technology makes complex stack geometries possible without the need for follow-up fine-tuning to meet precision requirements. Lamination stacks bonded using bonding varnish are compact and waterproof.

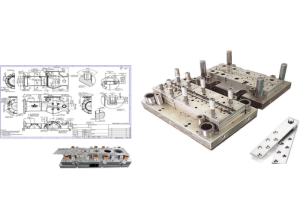

Bonded & Stamping Cores

Industrial Application

Bonded Cores are bound using special glue and applied on all types of motor cores upon a special need.

Technical Specification

Bonded & Stamping Cores are the most advanced form of technology, can improvise production speed and in parallel adhering to precision requirements sought, thus protect motor cores from moisture, dust and other contaminations.

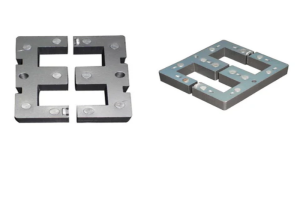

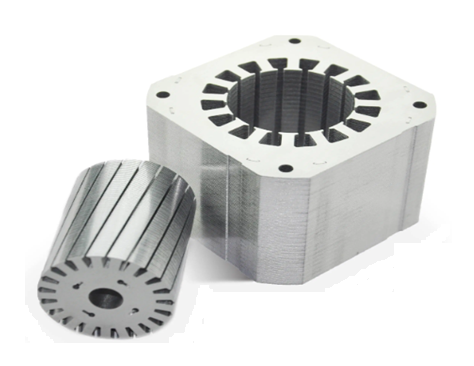

Electric Vehicle Stamping Cores

Industrial Application

Bonded stamping cores are widely used in Electrical Vehicle stamping cores for high-end efficiency in motors.

Technical Specification

Electric Vehicle bonded type stamping cores are bound using special glue adhering to precision requirements sought, thus protect motor cores from moisture, dust and other contaminations and are coated in special needs.

Welded Stator Cores

Industrial Application

Welded cores are widely used in bigger and thicker cores, suitable for all such stators in industrial application.

Technical Specification

Welded stator cores are bound through organic or tig welding process to maintain the stacked cores intact and maintain precision in parallel to achieve possible lowest watt loss and get higher motor efficiency.

Cleated Stator Cores

Industrial Application

Cleating is an another alternate to Interlocked type of cores type of cores.

Technical Specification

Cleated Stator Cores are stacked by galvanized or cold rolled strips in thickness of up to 2mm and cleating notches are in line with lamination tooth or slot opening, vary from 2 to 16 per stator depending on the size of the motor.

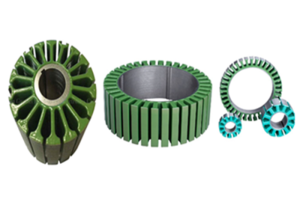

interlock magnetic cores

Industrial Application

Interlocked type of cores is widely used for almost all industrial applications.

Technical Specification

Interlocked magnetic cores are stacked automatically in the die system and are produced faster maintaining in parallel maintain precision enabling higher motor efficiency.

Customized Products & Specialization

Linear Motor Stampings