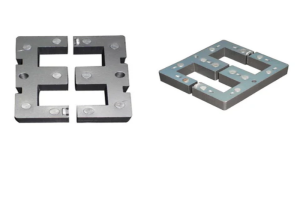

CRGO Miter Cut

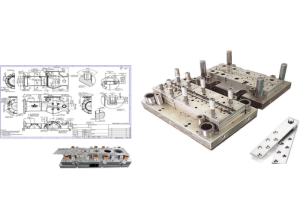

Electrical Steel Coils are punched and cut into certain shape and size in the production line, the classification and finishing work is completed at the end of the production line, and it is automatically stacked into 20 columns and used for the core assembly. The production line is used for shearing, O punching and V notch of transformer core sheet. The special point of this line is that two O punch and one V notch can work at the same time to produce transformer core pieces with 3, 5, 7 steps in vertical direction and 3, 5, 7 steps in horizontal direction. Any size and any length with and without Miter cutting can be achieved.

Miter Cut

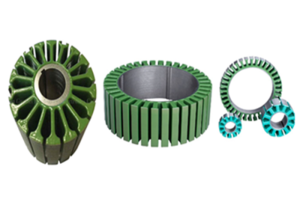

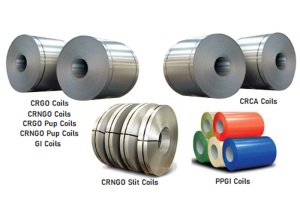

Industrial Application

Used in huge transformer applications thickness ranging 0.35 and 0.50 mm

Technical Specification

Mitre cut are bigger cores stacked into columns ranging up to 20 columns, punched in 3,5,7 steps in vertical direction and 3.5.7 steps in horizontal direction and are cut to any size and length as per the specific design for application sought.

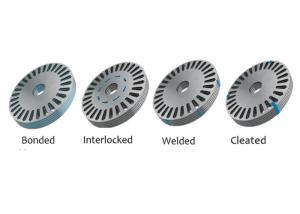

Customized Products & Specialization

Linear Motor Stampings