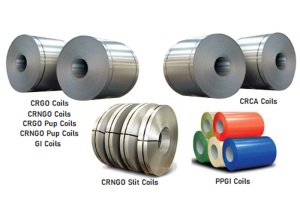

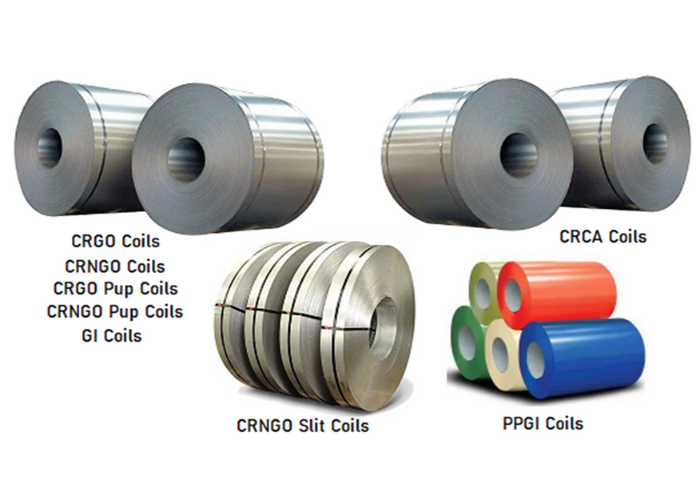

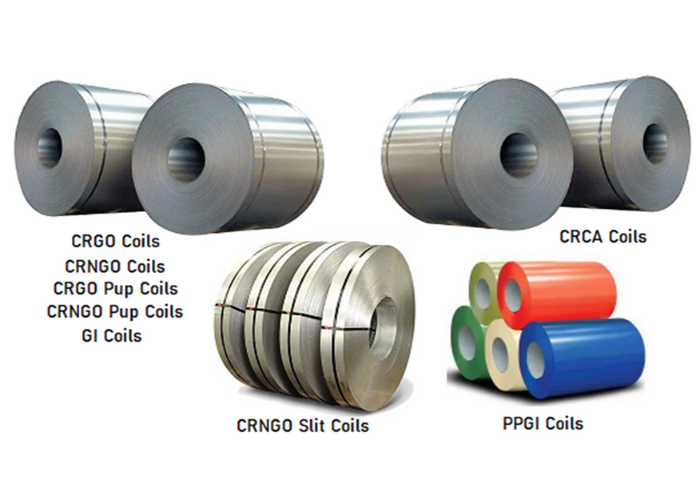

CRNGO, CRGO Slit & Master Coils

Master and Slit Coils are Coils supplied as it is or even in the slit form suiting the application required for and these coils are of silicon electrical steel grades that possess magnetic properties that are strongly oriented with respect to the direction of rolling. These grades are fully processed, but are generally given a final anneal to eliminate additional stresses exposed during the manufacturing process, for smaller part sizes or Cut to Length (CTL) products.

The materials are available in Fully-Processed (FP) or Semi-Processed (SP) condition. Fully-Processed electrical steel has had their magnetic properties completely developed by the mill. Semi-Processed electrical steel requires a final heat treatment known as Quality Development Anneal (QDA). For Fully-Processed material a Stress Relief Anneal (SRA) is required to achieve optimum magnetic performance. These grades are typically supplied with an insulating coating applied at the mill. Material can be supplied with C3, C4, C5 coatings types as specified by end user. Normally it will be in 1000 mm roll form and can weigh up to 4-5 tons.

Master and Slit Coils

Industrial Application

Coils are slit or supplied in original form to various industrial applications, basing specific requirement.

Technical Specification

Coils are of electrical steel grades possess magnetic properties that are strongly oriented with respect to the direction of rolling and these coils are also supplied with insulating coating ranging C3, C4 and C5 type.

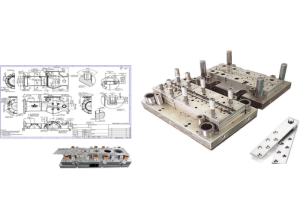

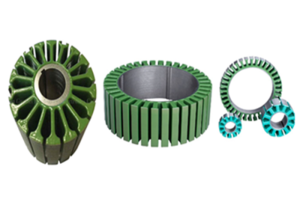

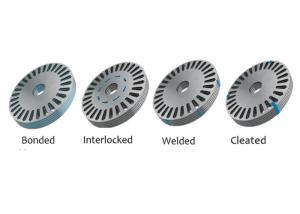

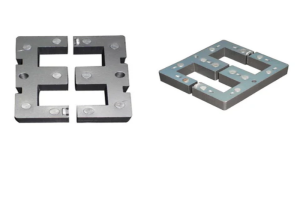

Customized Products & Specialization

Linear Motor Stampings