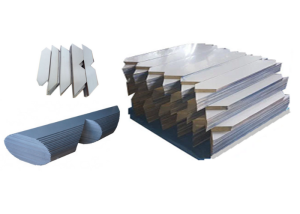

Strip Laminations

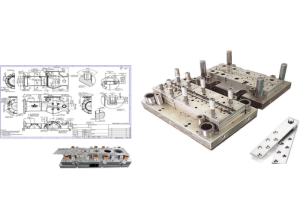

Strip Lamination are used where the transformer size is huge for power transformers and isolation transformers. Strip Laminations are made using special equipment for the production of transformer core of cross shear line. This production line is used for

shearing, O punching and to cut to required length of transformer core sheet. The special point of this line is that two O punch and shearing can work at the same time to produce transformer core pieces with 3, 5, 7 steps in vertical

direction and 3, 5, 7 steps in horizontal direction.

Strip Laminations automatic 90 degree cutting line for transformer core, and can cover up to the max sheet width of 300mm, hole size: φ8-25mm. Strip Laminations are made of tungsten carbide steel cutter with high reliability, the accuracy is ±0. 02mm, and the max cutting speed more than 240 pcs/min, automatic feeding, punching and cutting with high efficiency and high accuracy.

Strip Laminations

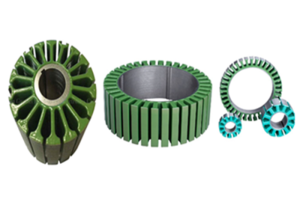

Industrial Application

Used in transformers of huge size for power transmission, in isolation transformers.

Technical Specification

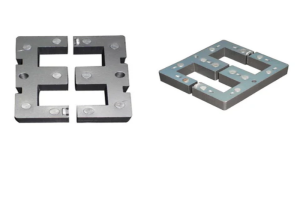

Strip laminations are made using special equipment for O punching and cut to required length of transformer core sheet to produce transformer core pieces with 3, 5, 7 steps in vertical direction and 3, 5, 7 steps in horizontal direction.

Customized Products & Specialization

Linear Motor Stampings